Most transformations don’t fail loudly or dramatically; they lose a slow, quiet tug-of-war against the familiar, long after everyone thought the hard part was over.

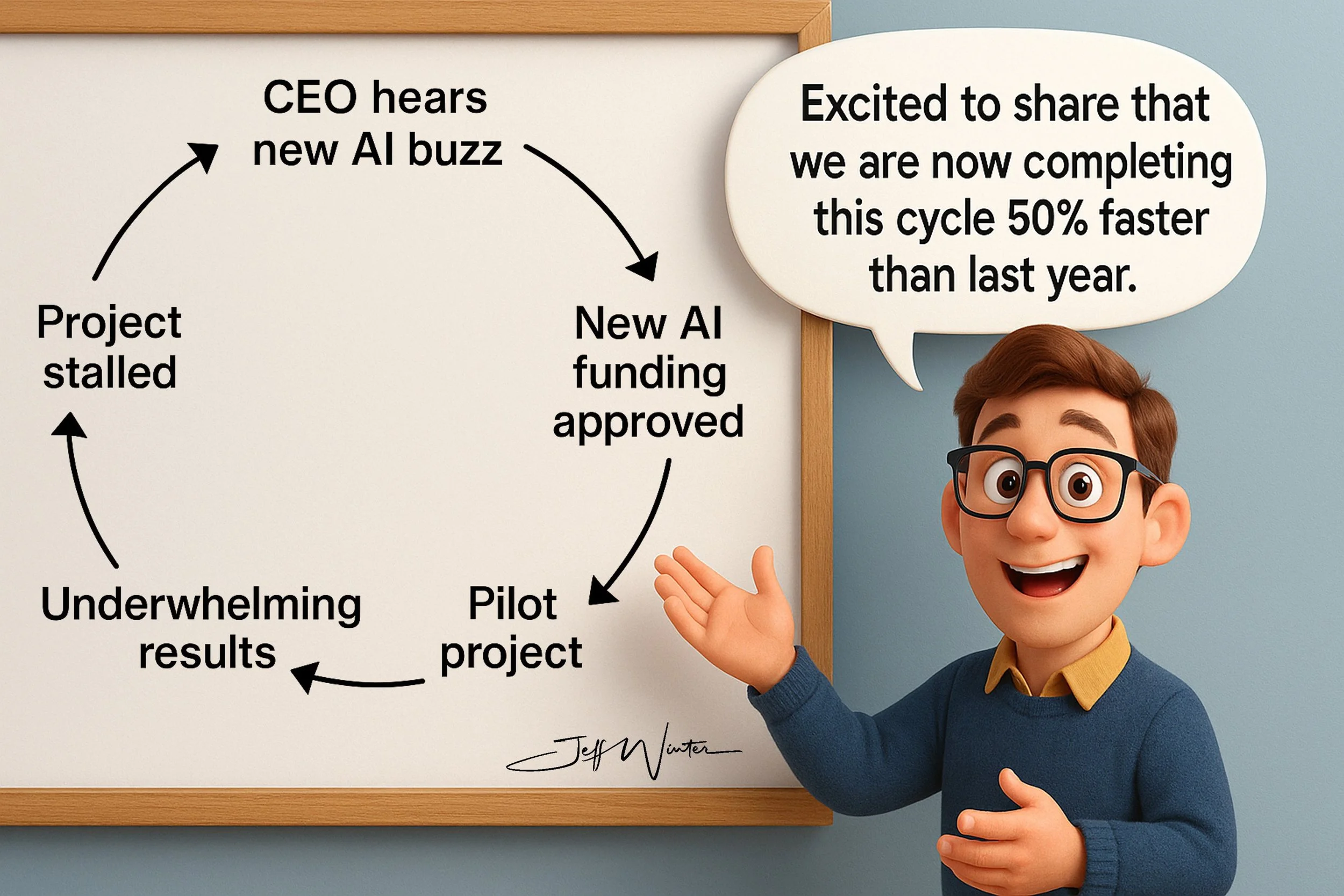

Most AI initiatives fail not because the technology isn’t smart enough, but because organizations never decide which decisions they’re willing to let go of.

A crooked 17th-century building becomes a metaphor for why stabilizing misaligned systems can preserve the past but quietly block progress when the goal is growth.

We love tidy slogans because they sound actionable and safe.

This article unpacks how a familiar transformation mantra was born, why it still shows up everywhere today, and where organizations consistently get tripped up when turning good intentions into real progress.

Manufacturing innovation does not have to be mysterious or overwhelming. These six simple levers offer a practical way to spot where innovation actually matters on the factory floor and turn big ideas into real operational impact.

OT security has finally made it to the CISO’s desk, but factories don’t run on org charts. This article explores why manufacturing is now the top cyber target, and what leaders must change to turn executive ownership into real operational resilience.

A Game of Thrones–inspired look at why modern manufacturers can’t compete by relying on instinct, hierarchy, or “the gods” to make decisions, and how data, AI, and real visibility finally give leaders the power to shape their own destiny.

A fun Terminator 2–inspired take on why modern manufacturing can’t transform without shared data, integrated systems, and actual human cooperation

A look at the real reasons digital and AI transformations collapse and what leaders must change to stay off the cover of any technology-failure magazine.

ROI is a superhero when used in the right places, a black hole when used in the wrong ones, and a discipline, not a deliverable, if you actually want it to work.

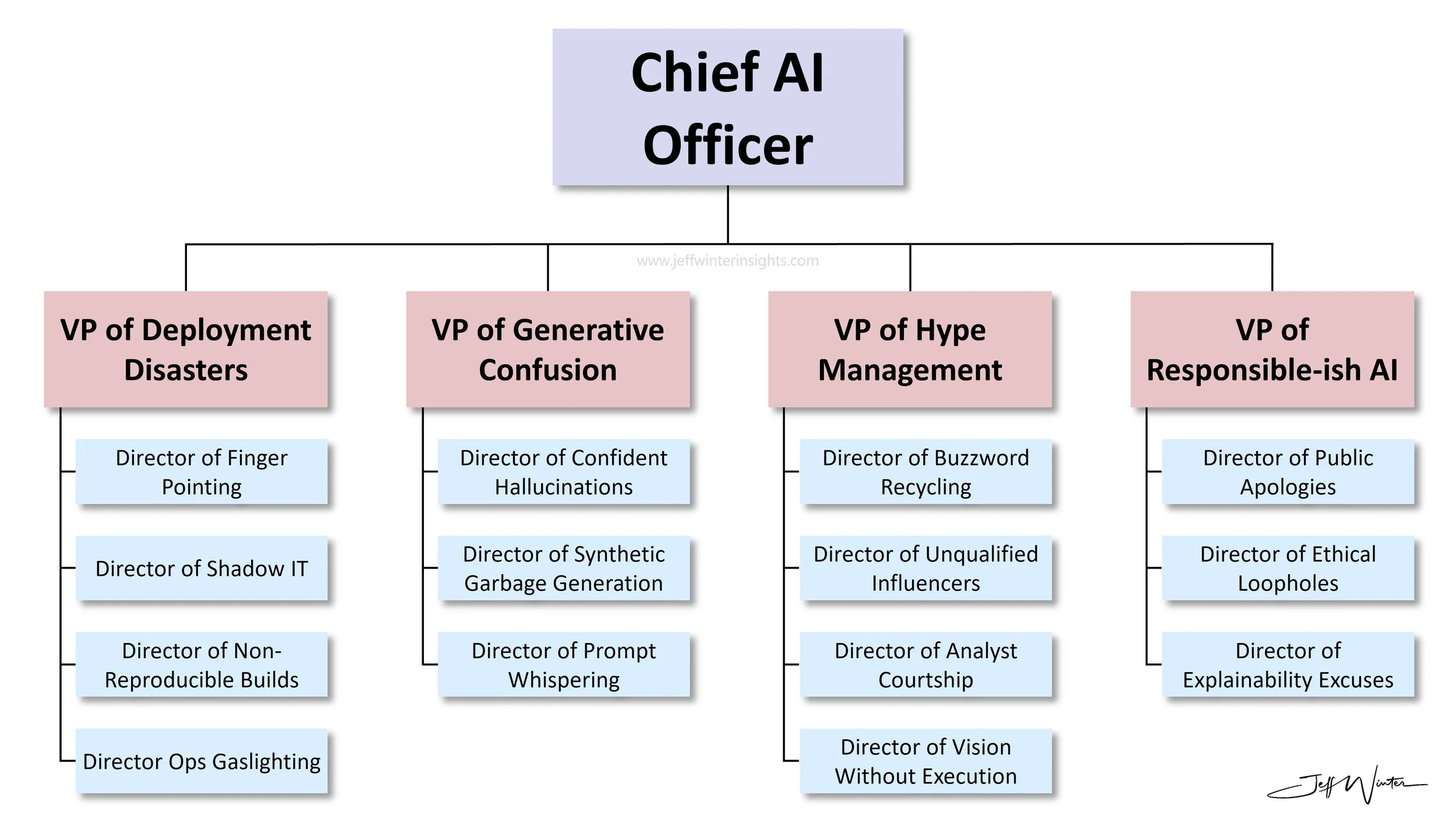

AI now touches employees, departments, and enterprise value all at once, sparking friction between CIOs, COOs, and everyone in between unless companies align on how work truly changes.

The real challenge isn’t blocking out AI noise, but sharpening the strategic signal that actually matters.

An entertaining look at why finding insights in today’s factories feels less like analytics and more like squinting at a crowded Waldo page hoping the answers reveal themselves.

Most companies call their efforts “digital transformation,” but if the operating model would function the same without the technology, then nothing transformative has happened, and this article explains why lasting change only occurs when the business itself evolves, not just the tools around it.

Generative AI gave us smart answers.

Agentic AI gives us autonomous action.

That jump is massive… and dangerous.

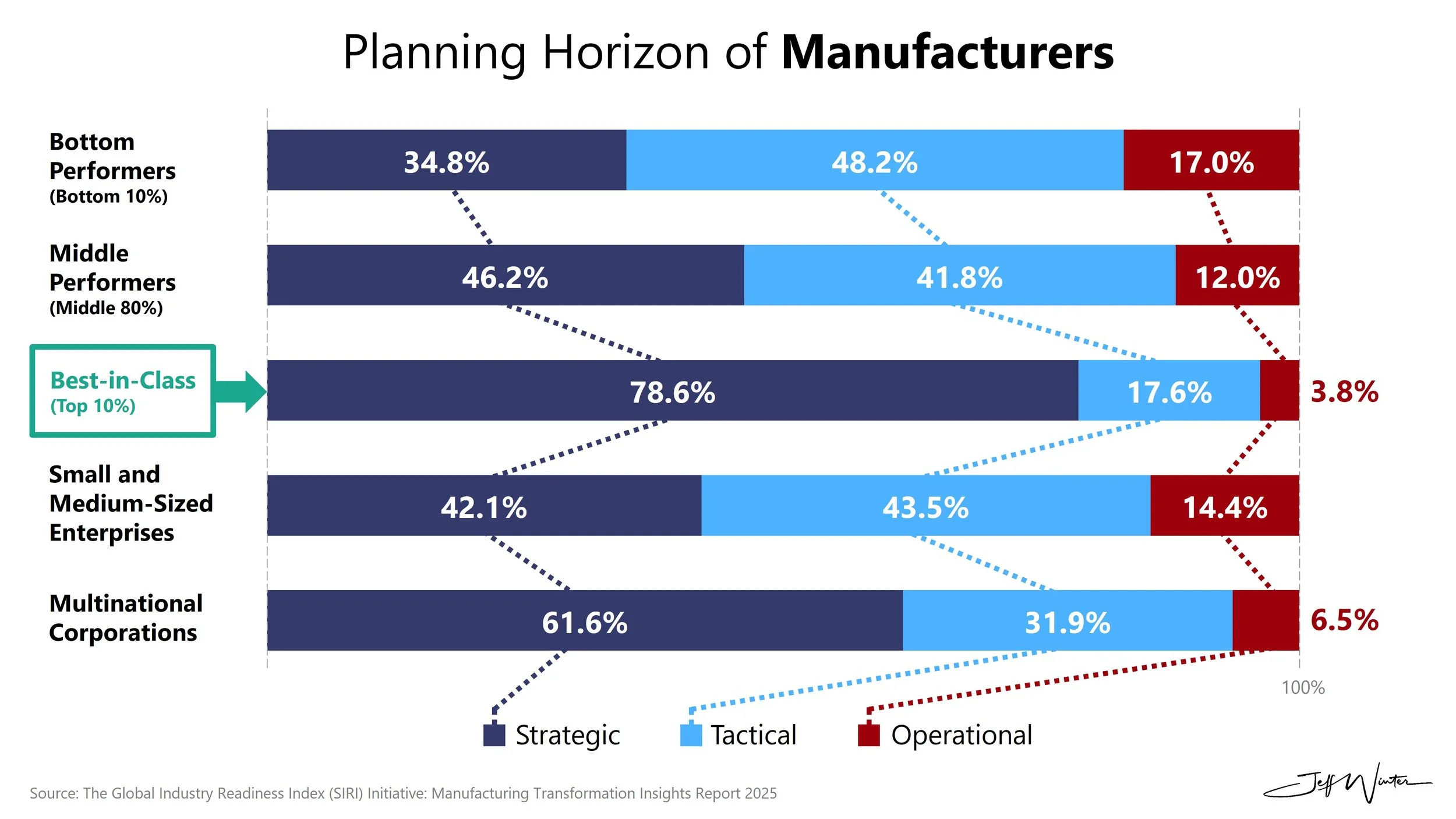

A practical guide for manufacturers on how to strengthen their digital transformation readiness, move faster with confidence, and turn uncertainty into advantage.

Factories have needs too. Just like Maslow taught us about people, manufacturers must climb their own pyramid.

Edge Computing Explained: From Shop Floor Sensors to AI-Powered Insights, Right Where the Work Gets Done

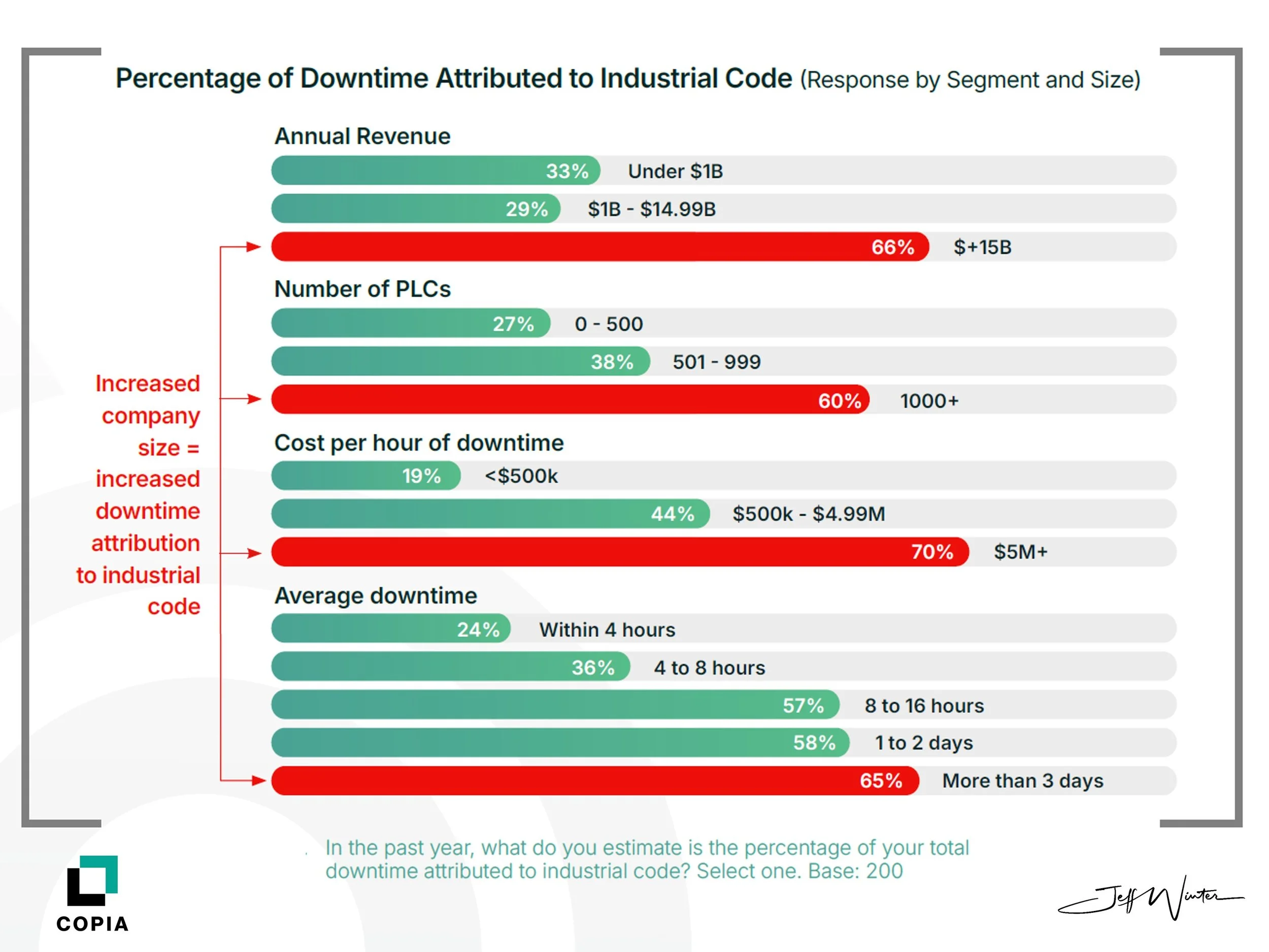

Every second counts on the factory floor, yet countless hours slip away due to messy code management.

Spreadsheets don’t win supply chains; intelligence does; the winners will be those who replace static rows and columns with living systems that think, learn, and respond.

Half-truths are more dangerous than lies. Because lies you can spot. Half-truths feel real. They give you just enough confidence to act… but not enough clarity to succeed.

Humanoid robots are closer than the debate suggests, because the real bottleneck is no longer intelligence.