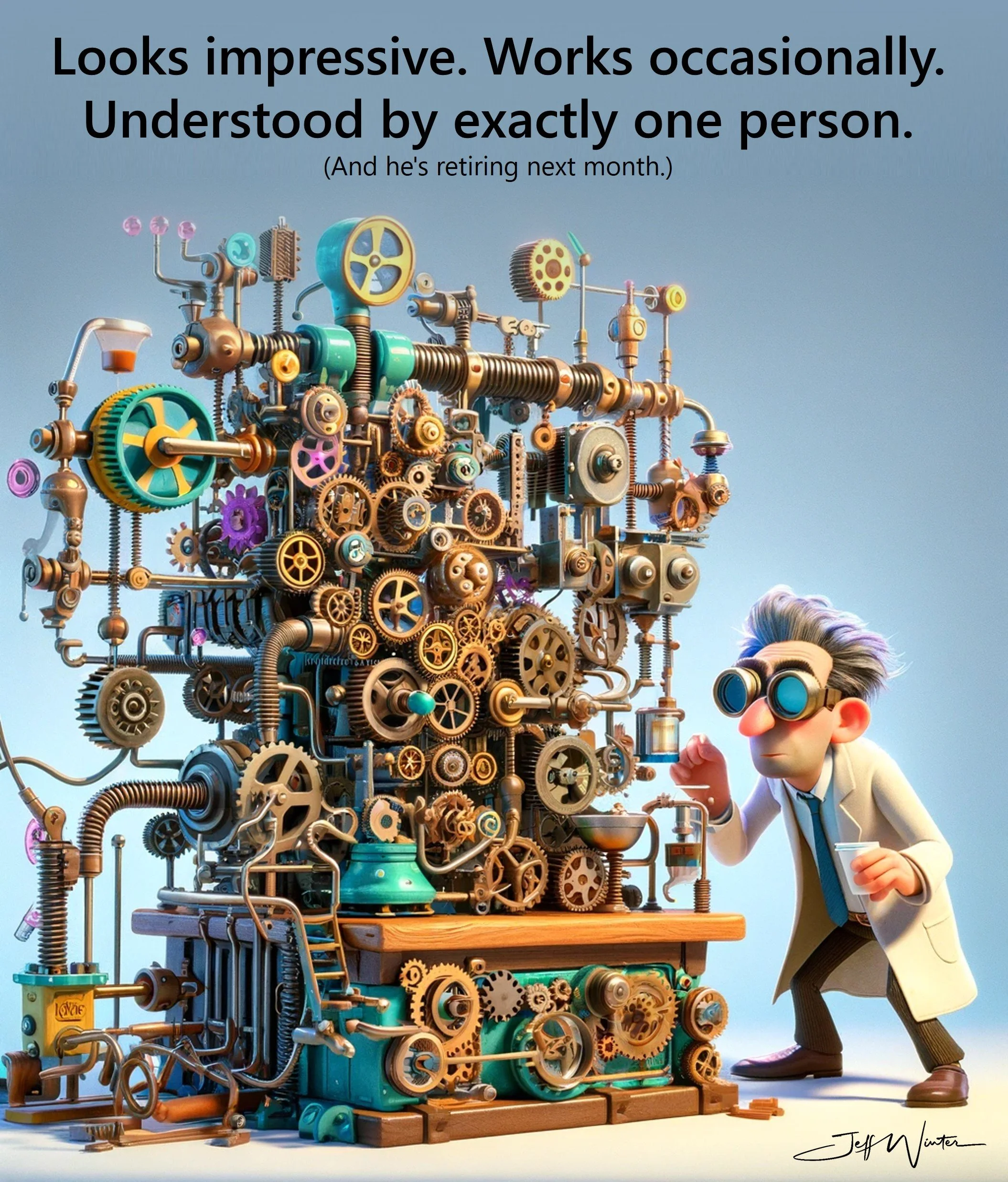

The Franken-System: Built to Survive, Not to Last

Everyone has that process.

The one that technically works, but nobody understands how.

And nobody dares touch it.

It’s the hidden workflow buried deep in your operation. Born from a string of patchwork fixes, duct-taped integrations, homegrown scripts, and tribal knowledge held by exactly one person. That person may or may not be approaching retirement. The process moves data. It triggers reports. It somehow still functions, but only if you follow the right steps in the right order and never ask too many questions.

At first glance, it might even look like innovation.

But look a little closer, and you realize it's just survival.

Welcome to the world of the Franken-system. A machine that is loyal, misunderstood, and often terrifying in the wrong hands.

It’s Alive... But No One Knows Why

The term Franken-system comes from Frankenstein, the novel written by Mary Shelley in 1818. Shelley was a groundbreaking English author often credited with creating the science fiction genre. Her story follows Victor Frankenstein, a scientist who assembles a living creature from parts of various corpses. He succeeds in giving it life but fails to consider the consequences. His creation is powerful and intelligent, but also unstable, unpredictable, and ultimately uncontrollable.

Franken-systems in manufacturing follow a very similar arc. They are born not out of malice, but out of necessity. Most start as clever solutions to specific problems. Maybe a script to speed up reporting. A quick Excel macro to fill a data gap. A “temporary” fix when a connector between systems could not be funded in time. Every step is logical in isolation. But over time, the logic gets buried, the creators move on, and the system becomes something nobody fully understands.

When it works, people praise its reliability. When it doesn’t, people panic.

Just like Frankenstein’s monster, these systems were not built to be evil. They were built without enough foresight.

What Is a Franken-System, Really?

A Franken-system is any core business or operational process that runs on a messy collection of outdated tools, half-documented rules, and custom fixes that were never designed to work together. It technically functions, and it often plays a critical role in day-to-day operations. But it is fragile. And it is risky.

Most manufacturers have at least one Franken-system hiding in plain sight. Here’s what they typically look like:

They rely on outdated or unsupported technologies. This could mean legacy databases, ancient versions of Excel, or homemade applications that no one wants to update.

Documentation is either missing or irrelevant. The current process only exists in the heads of a few people.

There are manual interventions everywhere. Someone is exporting a file, changing a format, and emailing it to someone else before the next step can begin.

One person understands the whole thing. Everyone else just knows not to touch it.

It fails randomly, but rarely enough that fixing it never becomes urgent.

These systems become deeply embedded because they were built to solve real problems. But as the business grows, they start to get in the way. And because they still technically work, they rarely get the attention they deserve.

Why Do Franken-Systems Happen?

Franken-systems are not the result of incompetence. They are born from good people doing their best with what they have. In high-pressure environments like manufacturing, the immediate need to keep production moving often outweighs the luxury of doing things the right way.

Here are some common reasons they take root:

Emergency fixes that were never revisited. Quick solutions become permanent solutions.

Different departments solving problems in isolation. Without shared ownership, systems are layered rather than integrated.

The cost of replacement feels too high. Budget constraints make modernization easy to delay.

Senior leaders see results, not processes. If the outcome looks good, no one questions how it was produced.

Critical knowledge lives in silos. When someone leaves or retires, their understanding leaves with them.

All of this creates a system that feels stable from the outside but is wildly complex and brittle on the inside.

How to Face the Monster You Built

You do not need to destroy the Franken-system in a blaze of glory. You simply need to acknowledge that it exists.

Modernization does not start with flashy technology. It starts with visibility and honesty. The first step is to understand what the current state really is. Not the process map that lives in SharePoint, but the actual steps people follow when things need to get done.

Walk the process. Follow the data. Ask the questions no one wants to ask. Why is this step manual? Who checks this report before it gets sent? What does that macro actually do?

Once you understand what the Franken-system is doing, you can make informed decisions about what to replace, what to improve, and what to leave alone for now. Begin documenting what you find. Assign clear ownership to each step. Eliminate fragile dependencies wherever possible. And when you rebuild, do it with transparency and long-term sustainability in mind.

Some companies try to skip this and jump straight to automation or artificial intelligence. But that only makes the problem worse. You cannot improve what you do not understand. And you certainly cannot scale it.

Before you build a smart factory, make sure you are not running it on haunted machinery.

The real lesson of Frankenstein is not about science or ambition. It is about responsibility. Victor Frankenstein failed not because he gave life to something unnatural, but because he walked away from what he created. He stopped paying attention. He abandoned the work.

You do not have to.