Making Industry 4.0 Work: Lessons from Jeff Winter on Change, Culture, and Technology

Originally published with Reliable Plant Magazine: https://www.machinerylubrication.com/Read/32936/making-industry-4-Work

Jeff Winter didn’t set out to become a leading voice in the world of Industry 4.0—at least not at first. What began as a line item in a job description quickly turned into a defining career path, as he found himself drawn not just to the promise of emerging technologies, but to the real-world transformation they could drive. With roots in industrial automation and a track record of building value from the ground up, Jeff developed a unique perspective on digital transformation: one that sits squarely at the intersection of strategy, technology, and execution.

We had the opportunity to sit down with Jeff and learn more about his journey—from launching new business lines in industrial safety to becoming a trusted advisor in smart manufacturing. In our conversation, he shared candid insights on the evolution of Industry 4.0, the cultural and operational challenges many organizations face in modernizing maintenance and reliability, and why bridging the gap between innovation and execution is more important now than ever before.

Q: Can you tell us a little about your background and what first sparked your interest in Industry 4.0?

A: I started my career in industrial automation, gaining hands-on experience in sales, marketing, operations, and strategy across hardware, software, and services. My first major leap came when I pitched and built a brand-new business line in industrial safety. That experience taught me what it takes to create value from scratch—and more importantly, how to spot real industry problems worth solving.

Then in late 2018, I was assigned to something I’d never even heard of at the time: Industry 4.0. It wasn’t a passion project—it was a bullet point in my job description. But as I dug in, I quickly realized this wasn’t just a buzzword. It was a tectonic shift in how manufacturers think, operate, and compete. I didn’t choose Industry 4.0—it chose me. And I stayed.

What kept me in it wasn’t just the technology. It was the joy of watching an entire industry transform—and being able to help individual companies navigate that transformation through smart, strategic use of emerging technologies. I found purpose in bridging the gap between innovation and execution.

So I leaned in. I built and led teams focused on digital transformation. I got involved in academic groups, industry research teams, and advisory boards to stay ahead of the curve. And I committed to turning my personal brand into a platform—so I could inspire others, simplify the complex, and drive real impact at scale.

For me, Industry 4.0 is more than a trend. It’s an opportunity to reimagine what’s possible—and to make sure this era of transformation actually delivers.

Q: Looking back, how has your perspective on maintenance and reliability evolved since you first got involved with Industry 4.0?

A: When I first got involved in Industry 4.0, I’ll be honest—maintenance and reliability weren’t front and center. My focus was more on automation, integration, and the broader digital transformation landscape. But the deeper I got into Industry 4.0, the clearer it became: maintenance is a key area where many companies either quietly succeed… or painfully fall behind.

My perspective evolved as I saw how much untapped potential there was in using analytics and AI to predict failures before they happen—not just to avoid downtime, but to drive efficiency, safety, and cost savings across operations. Predictive maintenance isn’t just a buzzword. When done right, it’s a strategic advantage.

That realization led me to dig deeper into the topic—so much so that I ended up writing a feature article for MaintenanceWorld.com in 2024, where I explained the concept of Maintenance 4.0. It was my way of helping others see what I had come to understand: maintenance in the Industry 4.0 era isn’t reactive or even scheduled. It’s intelligent. It’s connected. And it’s foundational to a truly smart factory.

Today, I see maintenance not as a back-office function, but as one of the biggest levers companies can pull to drive operational excellence—especially when powered by the right data, the right tools, and the right mindset.

Q: From your perspective, how does Industry 4.0 reshape traditional maintenance strategies?

A: For decades, maintenance was reactive: fix it when it breaks. Then came preventive maintenance—scheduled servicing, often based on assumptions rather than reality. But Industry 4.0 changes the game entirely. It takes maintenance from the shadows and puts it at the center of operational strategy. We’re no longer just maintaining machines—we're maintaining performance, uptime, quality, and cost control.

The biggest shift? Data. With IoT, sensors, and AI, we can now move beyond reacting and guessing to predicting and prescribing. Maintenance becomes proactive, driven by real-time data and analytics, not just spreadsheets and gut instinct. The equipment doesn’t just operate—it communicates. It tells us when it’s under stress, when it’s nearing failure, and what to do about it before problems occur.

But Maintenance 4.0 goes beyond prediction—it connects maintenance to operations, production planning, supply chain, and asset performance management. It helps reduce unplanned downtime, extend asset life, optimize resource allocation, and drive significant cost savings. In fact, some companies are seeing up to 40% reductions in unplanned downtime and 30% lower maintenance costs with this approach.

This transformation also reshaped my thinking. Maintenance is no longer a cost center—it’s a value center. With the right data architecture, analytics, and mindset, maintenance teams become reliability engineers, data interpreters, and operational forecasters. Their work feeds into the bigger picture—supporting everything from lean initiatives to sustainability goals.

What excites me most is the cultural shift: bringing maintenance into the conversation earlier, integrating it into AI strategies, and aligning it with the broader goals of digital transformation. In many ways, maintenance is becoming the proving ground for Industry 4.0’s promise.

And honestly? That’s what keeps me engaged. Watching an old function evolve into a strategic powerhouse—and helping others connect those dots—is exactly the kind of transformation I’m here for.

Q: Predictive and prescriptive maintenance are often seen as the end goals — but what do you think is the most overlooked step in getting there?

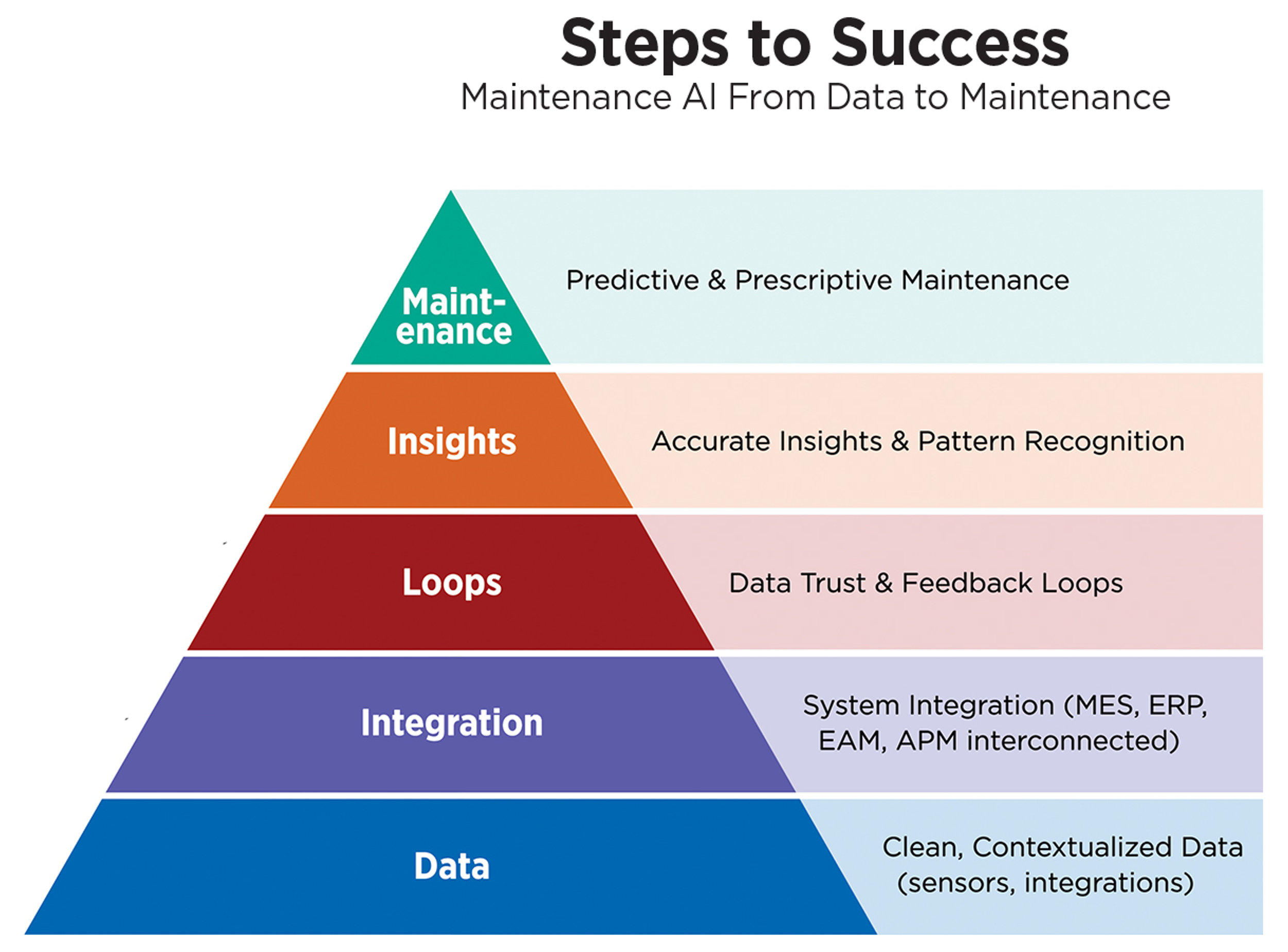

A: The most overlooked step is building the right data foundation—and doing it intentionally. Everyone’s in a rush to deploy AI models or jump into predictive and prescriptive maintenance, but they skip over the groundwork that actually makes those tools effective.

It’s not just about slapping sensors on machines. It’s about capturing the right data, in the right context, at the right time—then making sure that data flows seamlessly between systems like your Manufacturing Execution System (MES), Enterprise Resource Planning (ERP), Enterprise Asset Management (EAM) and Asset Performance Management (APM). Without that integration, insights stay siloed, and your AI becomes little more than a glorified guess engine.

Equally important is building trust in the data. Maintenance teams won’t act on predictions unless they’re confident the insights are accurate and meaningful. That requires clean data, transparent logic, and a solid feedback loop. You can’t predict the future—or prescribe anything useful—if you haven’t first built a reliable picture of the present.

Q: Many organizations struggle to move from reactive maintenance to a predictive model. What are the biggest cultural or technological roadblocks you’ve seen?

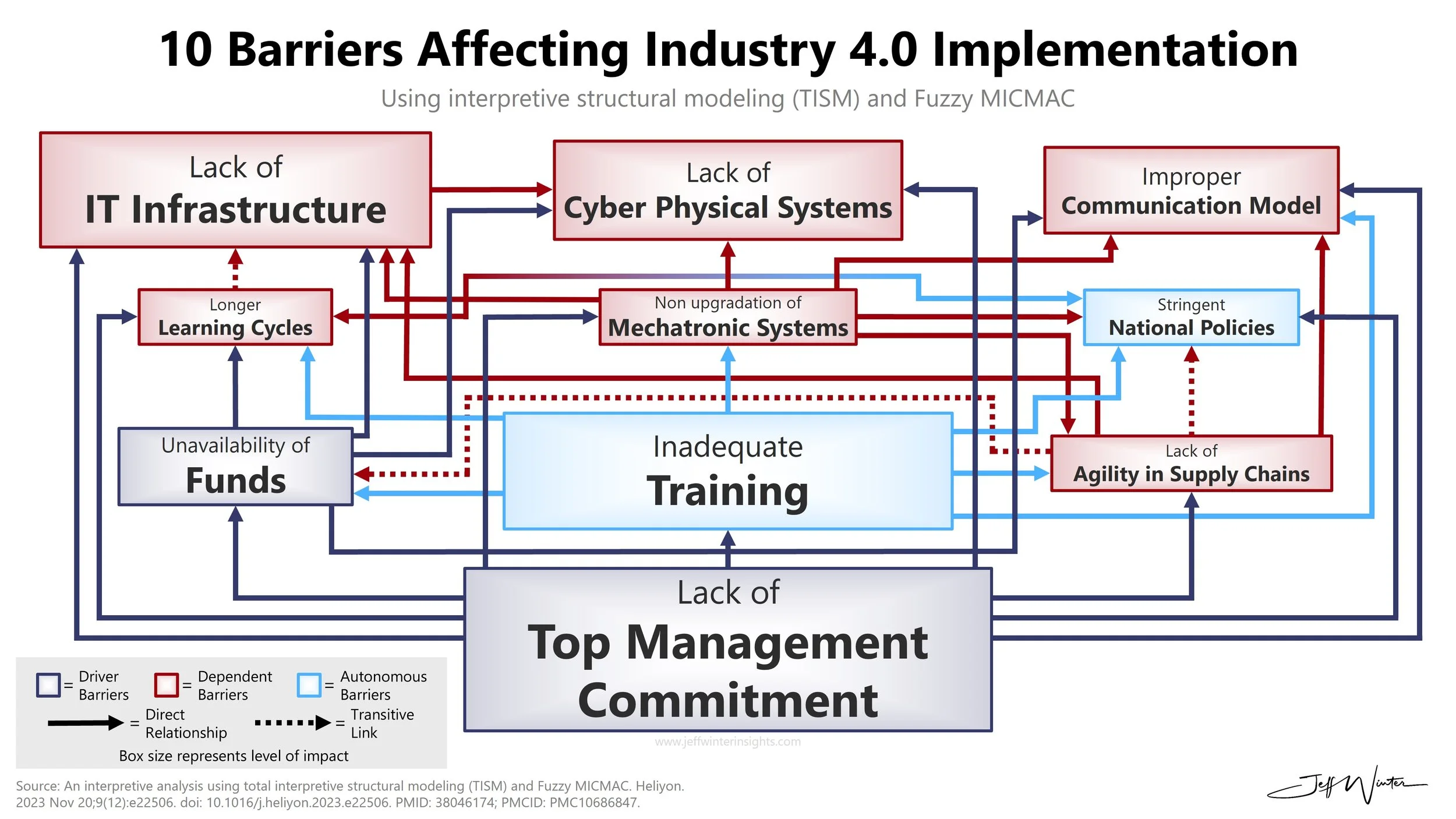

A: One of the biggest cultural roadblocks I’ve seen is clinging to the old mindset: “If it ain’t broke, don’t fix it.” That was the motto of Industry 3.0—where stability and efficiency were the goals. But in Industry 4.0, I like to say: “If it ain’t broke, digitize it anyway.” Because today, it’s about agility, adaptability, and innovation. Things are changing too fast, and waiting for something to break before acting is a recipe for falling behind.

Another major roadblock is the perception that predictive maintenance is an IT project rather than an operational shift. Too often, initiatives are driven by tech teams without deep involvement from the people who actually run and maintain the equipment. That disconnect creates resistance—because when predictive tools feel imposed rather than integrated, they get ignored.

There’s also a skills gap that rarely gets talked about. Moving to predictive models requires new capabilities—understanding analytics, interpreting trends, and trusting machine-generated insights. Many maintenance teams have decades of hands-on expertise, but little exposure to data science or AI. Without proper training and cross-functional collaboration, even the best technology ends up underutilized. To succeed, organizations need to treat this as a human transformation just as much as a digital one.

Q: How can maintenance and reliability teams balance the need for digital tools with the human knowledge and intuition that many experienced technicians bring to the table?

A: The key is to treat digital tools as enhancements, not replacements. Predictive analytics and AI can surface patterns and early warnings, but it’s the seasoned technicians who provide the context, judgment, and nuance. The best results come from pairing machine insights with human intuition in a continuous feedback loop. When tech empowers technicians—rather than sidelining them—you get smarter, faster, and more reliable decisions.

Q: When companies begin their Industry 4.0 journey, they often collect data before knowing what to do with it. What’s your advice for turning raw data into actionable insights?

A: When companies begin their Industry 4.0 journey, one of the first things they do is collect data—often in massive quantities—without a clear plan for how to use it. That’s not inherently wrong. Data is the raw material of digital transformation. But just like raw materials on the shop floor, data doesn’t add value until it’s processed, contextualized, and applied with purpose. My advice? Don’t chase the data—shape it into insight.

Industry 4.0 was never just about sensors or AI—it was about creating a smarter, more responsive, and interconnected industrial environment. The original vision introduced at the Hannover Fair in 2011 imagined a future where factories weren’t just automated, but intelligent. And while that future is now very real, many companies still struggle because they focus on collecting more data rather than enabling better decisions.

The most common mistake I see is starting from the top—investing in AI, digital twins, or dashboards—without strengthening the bottom: execution. You can’t analyze what you can’t understand. That’s where MES becomes critical. It’s not just a system for tracking work orders; it’s the connective tissue that brings data to life. MES gives data context—tying it to time, location, shift, batch, operator, and machine. Without that, your AI model might know something went wrong but not why or what to do about it.

If you're swimming in raw data, start by anchoring it to execution. What decisions need to be made faster? What processes could be more consistent? What insights could reduce downtime or improve yield? Then look at connectivity—are your systems integrated and speaking the same language? Only once you have a clear execution layer and a connected environment does analysis start to deliver meaningful value.

Turning raw data into insight isn’t a technical problem—it’s a structural one. It requires building a data strategy that aligns with how work is done on the shop floor. And it’s why I say Industry 4.0 is a bottom-up transformation disguised as a top-down strategy. If your foundation isn’t strong, every insight is built on noise.

Ultimately, raw data becomes valuable when it supports decision-making—at the speed of operations. And the companies that get this right aren’t the ones collecting the most data… they’re the ones making the best use of it.

Q: What are some common misconceptions about digital transformation in the maintenance and reliability space?

A: One of the biggest misconceptions is that digital transformation in maintenance is just about installing sensors or buying predictive maintenance software. In reality, it’s a full shift in how maintenance is planned, executed, and integrated into operations. Many think AI will magically fix everything—but without good data, solid processes, and organizational buy-in, it won’t deliver. Another common myth is that experienced technicians will be replaced by machines, when in fact their knowledge is critical to interpreting insights and refining models. Some also believe transformation is a one-time project, but it’s really an ongoing journey that evolves with the business. And perhaps the most dangerous misconception? That you can just “plug in” a digital solution and get immediate ROI—when what’s actually needed is a clear strategy, aligned goals, and cross-functional collaboration to make it stick.

Q: In your opinion, what role do cross-department collaboration and leadership play in the success of digital transformation initiatives?

A: Digital transformation without cross-department collaboration is like trying to assemble IKEA furniture without the instructions—technically possible, but you’re probably going to end up with extra parts and a very wobbly shelf. The reality is, no single department has all the context. Maintenance knows the machines, operations understands the flow, IT manages the infrastructure, and leadership holds the purse strings. If they’re not working together, you're not transforming—you’re just installing tech and hoping for magic.

Too often, digital initiatives get trapped in departmental silos where each team optimizes their corner of the world, while the big-picture value gets lost in translation. And that’s exactly why strong leadership matters. Not just to fund projects or make nice speeches, but to set the vision, align incentives, and create a culture where collaboration is the default, not the exception.

Great leaders treat digital transformation like a company-wide upgrade—not just a new system, but a new way of thinking. They bring people together, break down “not my job” mentalities, and make sure that every stakeholder—from the plant floor to the boardroom—knows how their role fits into the bigger mission. Because let’s face it, digital tools are powerful, but they’re not miracle workers. Without people working together toward a common goal, they’re just shiny toys collecting dust.

Q: As Industry 4.0 technologies mature, what do you think the future of maintenance and reliability will look like over the next 5 to 10 years?

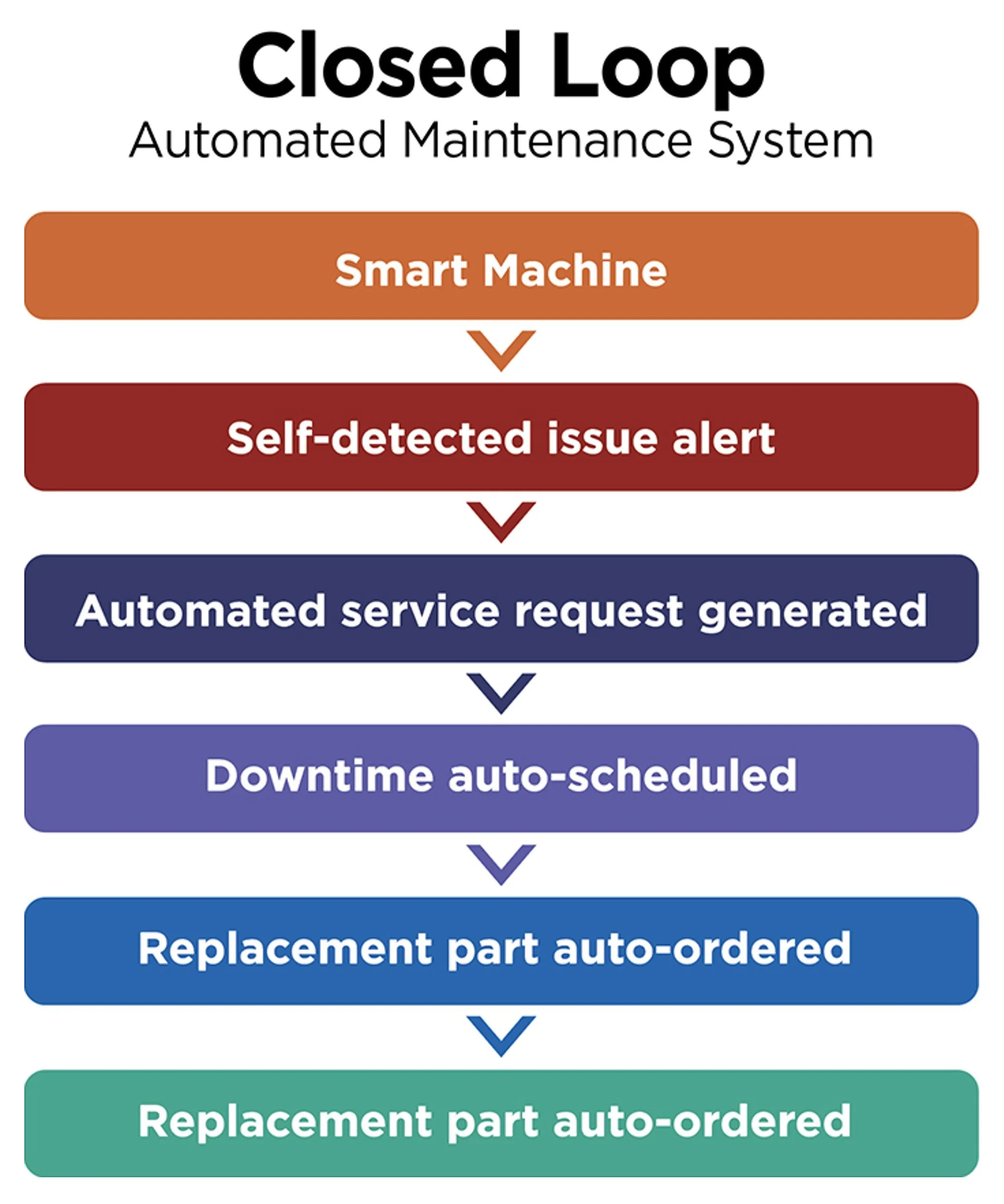

A: In the next 5 to 10 years, maintenance and reliability will shift from being operational support functions to strategic drivers of competitiveness. We’ll see a move toward autonomous maintenance ecosystems—where machines not only detect issues but initiate their own service requests, schedule downtime, and trigger part orders without human intervention. AI will play a much more active role, not just in predicting failures, but in continuously learning from operational data to fine-tune performance in real time.

Technicians won’t be replaced, but their roles will evolve. They’ll become hybrid problem-solvers, blending hands-on mechanical expertise with digital fluency—interpreting data, working with digital twins, and collaborating with AI systems. Maintenance strategies will be deeply integrated with production planning and supply chain systems, enabling real-time decision-making across the enterprise.

We’ll also see the rise of maintenance-as-a-service models, where OEMs and service providers monitor equipment health remotely and manage uptime as part of a contractual guarantee. And as sustainability pressures mount, reliability efforts will tie directly to energy efficiency, carbon reduction, and resource optimization—making maintenance not just about asset health, but about corporate responsibility and long-term value creation.

Q: If you could give one piece of advice to an organization hesitant about adopting Industry 4.0 tools for maintenance, what would it be?

A: Don’t mistake the current era for a passing trend. Industry 4.0 isn’t a buzzword—it’s the era we are living in. It reflects the fundamental shifts already happening across manufacturing: smarter machines, connected systems, AI-driven insights, and data as a competitive asset. Yes, people use “Industry 4.0” as a vision of where we’re going—but that vision is rooted in the reality of today’s changes.

So if you haven’t started yet, the question isn’t should you adopt these tools—it’s how will you compete with the companies that already have? Because they’re not just fixing things faster—they’re operating more efficiently, predicting problems before they happen, optimizing resources, and scaling with precision. Hesitation might feel safe, but in a world where agility wins, standing still is the fastest way to fall behind.