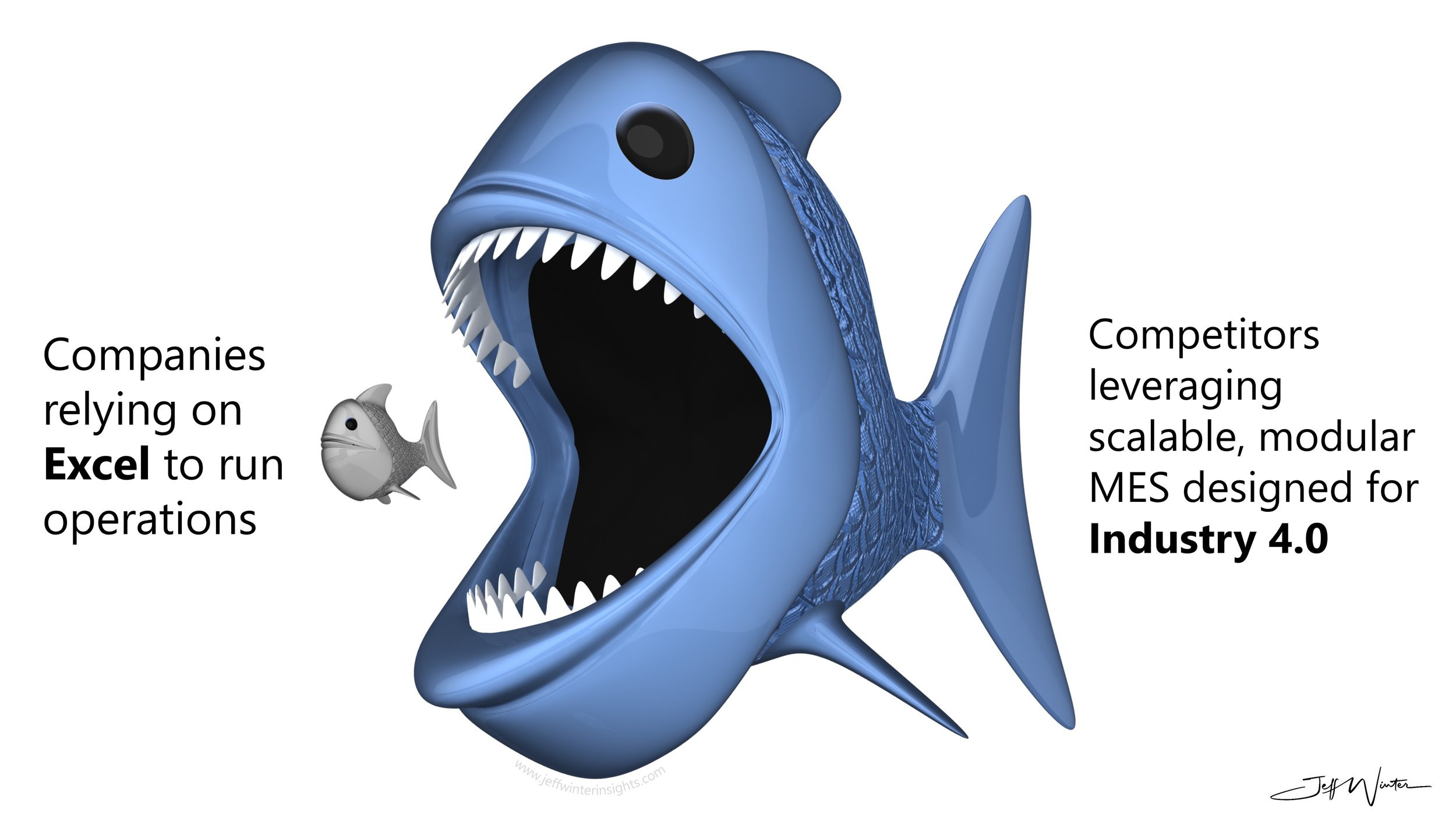

You Can’t Scale Excellence with Spreadsheets

If your operations still run on Excel... this might be the part where you start hearing the Jaws theme.

Welcome to the most anxious party on the planet: the factory floor where an Excel spreadsheet is steering the ship. Whether you think of operations as a strategic asset (growth engine, innovation driver) or merely a cost center (budget line to trim), one thing’s true in either case: flawless execution is mission-critical. If you’re a believer, you want production humming to capture markets and margin. If you’re a tight-fisted bean-counter, you need every widget out the door on time to avoid waste. But regardless of your view, the real world doesn’t care – orders still have to get made, rework fixed, and schedules met. Strategy only pays off when the rubber meets the road (or the drill hits metal).

Strategic Asset vs. Cost Center

Strategic asset: You see manufacturing as the cash cow or innovation engine. You want top-line lift and brand value from efficiency, quality and flexibility. In this view, the shop floor is where competitive advantage is realized: new features, new products, new capacity.

Cost center: You treat manufacturing like a utility — keep it running lean and cheap. You cut fat, squeeze overhead and focus on reducing defects and delays. The goal here is to shrink the operating budget with every scrap part avoided and uptime maximized.

Whichever camp you’re in, remember: strategy lives or dies in execution. A fancy plan isn’t worth a stack of reports if the line goes down or the wrong spec is built. Every shift without hiccup yields profit or saves costs. Conversely, missed deadlines and quality escapes hurt margins and reputation.

MES: The Real-Time Execution Engine

This is precisely why manufacturers are moving beyond spreadsheets toward real-time MES (Manufacturing Execution Systems). An MES is the “digital solution specifically designed to manage and monitor the production process” on the shop floor. In practice it executes the plan: collecting data from machines, scheduling work orders, and feeding results back to planners and management. It bridges the gap between ERP/PLM strategy and day-to-day reality. By running the “engine room” digitally, MES gives you instant visibility and control over every work order, machine and operator, without the manual translations. Metrics and updates aren’t stuck in a cubicle – they flow live from the line. In short, MES turns your high-level operations strategy into bolts, beams and bytes in real time, rather than static cells in a spreadsheet.

Why Spreadsheets Are a Recipe for Disaster

Despite all this, most factories still turn to spreadsheets like a security blanket. According to the Manufacturing Leadership Council in a 2024 Survey about 70% of manufacturers still collect production data manually (often via Excel, paper or phone calls) and 68% admit spreadsheets are their go-to tool for analysis. In other words, Excel is basically the world’s most-used defacto MES. That should set off alarms.

Putting so much responsibility on static sheets is risky business. Consider these pitfalls:

Error-prone: Spreadsheets beg for typos and bad formulas. In fact, a 2024 study led by Professor Pak-Lok Poon found 94% of business-critical spreadsheets contain errors. One bad cell on the shop floor can mean wrong part builds, inventory overages, or billing mistakes – each with serious costs.

No Real-Time View: Excel data is only as fresh as the last save. By the time you copy and paste updates, make rounds, or send reports, the factory has already moved on. Delays mean decisions on old info – a recipe for missed opportunities or firefighting.

Siloed and Unscalable: Everyone ends up with their own version of “the truth.” Different shifts or departments keep separate files, creating rework and confusion (“Which was the latest revision?”). Unlike an integrated system, you can’t automatically roll up data or trigger alerts across a plant in Excel – it’s all manual consolidation.

Hidden Costs: All that manual paperwork and copy/pasting isn’t free. That’s profit literally eaten by chasing down data, filling forms and fixing mistakes – every month.

In short, relying on Excel today is like trusting a tricycle in a Formula 1 race. It’s quaint, familiar – and woefully underpowered.

Time to Level Up Your Digital Maturity

Operations execs, consider this your wake-up call. If your shop floor still runs on spreadsheets, it’s time to reassess your digital maturity. Map out which processes are still cobbled together with paper and cells. Measure the time lost and errors made. Then, make a plan to tighten that gap between strategy and execution. Even starting with one process can pay dividends.

Audit and quantify: Identify where Excel and manual steps dominate (scheduling, quality logs, inventory counts, etc.). Calculate the delays, scrap and overtime caused.

Benchmark maturity: Compare your operation against Industry 4.0 best practices. Are you the plant where data flows freely, or the one where workers whisper numbers at shift change? Document the vision: better responsiveness, fewer mistakes, full traceability.

Invest in tools: Evaluate MES or other digital execution tools that fit your needs. Look for systems that automate data collection, integrate with existing IT, and empower frontline staff with real-time dashboards.

Pilot and expand: Roll out changes in stages. A successful pilot on one line or shift proves the value. Use that momentum (and some quick wins) to bring others on board.

Remember: in today’s fast-paced market, spreadsheets shouldn’t run the show. The days of honoring the sight of a green grid and comma-delimited fields as “factory control” are over. Modern MES-driven execution gives you a fighting chance to meet your goals – whether those are growth or cost-cutting (and we know you’ve got both on the table). Don’t let a formula error or a lost cell in Excel be what sinks your ship.

It’s time to get serious about digital operations. Embrace tools that connect your strategy to the shop-floor and stop hearing that ominous theme music every time a spreadsheet opens. Your next competitor won’t be kind enough to wait for you to press F9 on your last pivot table.

References:

Manufacturing Leadership Council - Seventy Percent of Manufacturers Still Enter Data Manually, August 2024: https://nam.org/seventy-percent-of-manufacturers-still-enter-data-manually-2-31811/

Poon, PL., Lau, M.F., Yu, Y.T. et al. Spreadsheet quality assurance: a literature review. Front. Comput. Sci. 18, 182203 (2024). https://doi.org/10.1007/s11704-023-2384-6